The resources of our bar turning and machining firm

Our smart organisation makes all the difference worldwide when it comes to precision mechanics

Being a go-to player in bar turning and precision CNC machining for customers in France and worldwide calls for specific skills, a fleet of machines at the cutting edge of technology, a swath of certifications and a network of qualified suppliers. We have all these resources and use them to meet the needs of our international markets.

The BENOIT JOLIVET name is synonymous with the assurance of French expertise based on almost a century of machine tools using the very latest techniques to produce precision mechanical parts. We’re a French partner you can trust for your projects.

Find out more about BENOIT JOLIVET, a bar turning firm recognised worldwide!

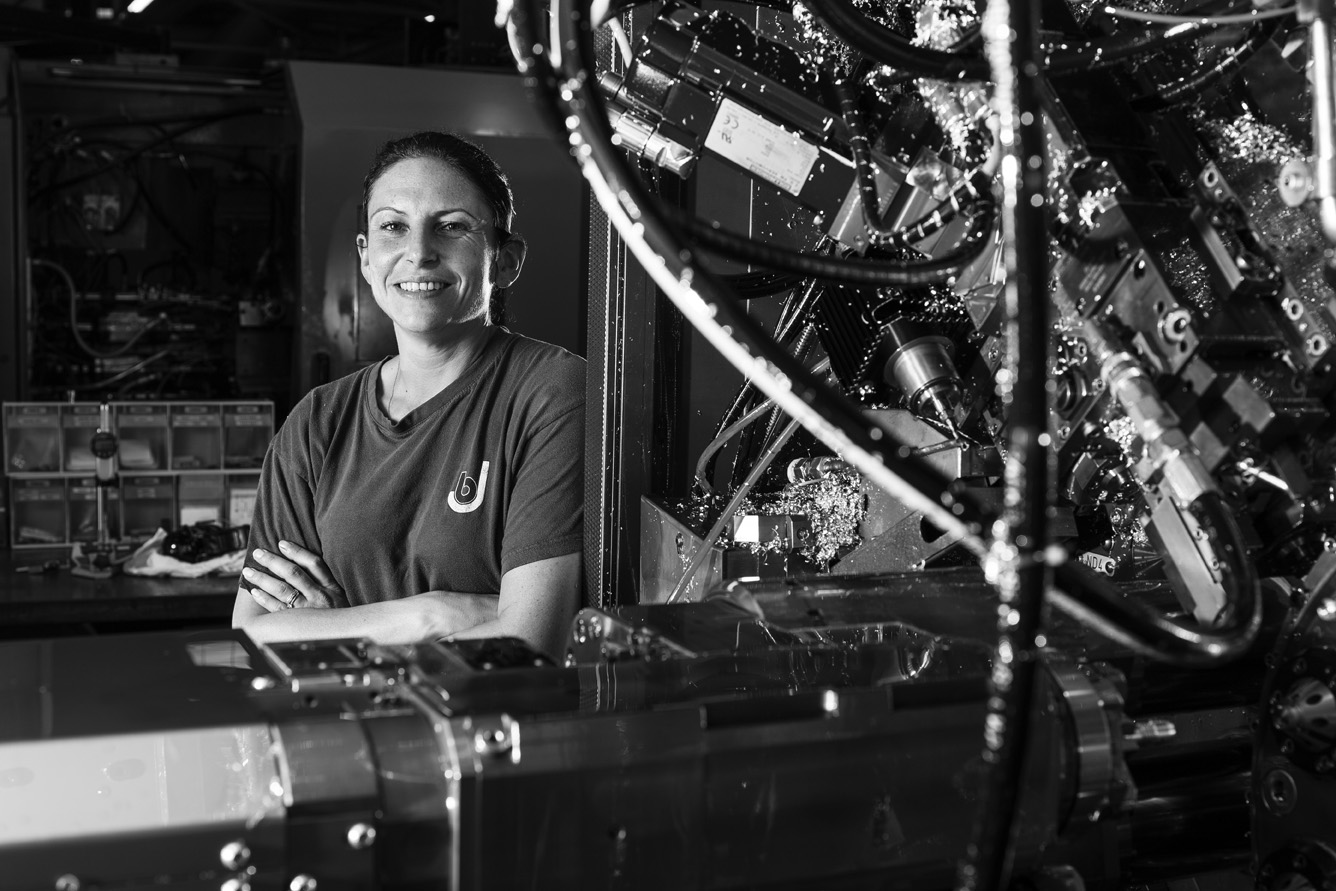

BENOIT JOLIVET is a company engaged in bar turning and precision CNC machining with a distinctive character that can be summed up in one word: organisation.

We control the entire manufacturing cycle, from the purchase of raw materials through to the final stages of machining, including specific operations such as precision grinding, lapping, heat treatment and surface treatments as required.

All these assets contribute to a common goal: delivering satisfaction for all our customers.

Precision bar turning: a machine fleet at the cutting edge of technology in our machining facility

In all, we have a qualified team of some 52 people working on over 80 high-tech machines installed in a 7000sqm production facility designed to meet expectations worldwide.

We’re fully aware of the issues raised by technology advances in our business, and invest every year to ensure we stay at the cutting edge of precision bar turning and machining internationally.

- 30 multi-spindle lathes (6-8 spindles / CNC 6-8 spindles): Index MS32, Index MS22, Tornos multideco, Schütte AF32S, Schütte SF 26-42-51, Tornos SAS 16

- 14 single-spindle CNC lathes: Tornos EVODeco, Deco 2000, Tornos ENC

- 10 Wirth & Gruffat rotary transfer machines (4-6-8-12 work stations – 8 CNC work stations)

- automatic optical control machines

- 1 Mitutoyo coordinate measuring machine

- 3 Tesascan measuring machines

- 1 Mitutoyo Roundtest roundness and position tolerance measuring machine

- 1 Mitutoyo Formtracer contour and surface roughness measuring machine

- 1 Fischerscope X-ray XDL surface treatment thickness measuring device

- 1 Rockwell hardness and Vickers micro-hardness measuring machine

- A wide variety of measurement resources and equipment, in particular to control for particulate matter pollution

- All standard apparatus required for statistical and one-off controls.

- Special analysis and controls at France’s Technical Centre for Mechanical Industries (Centre Technique du Décolletage, CETIM)

- Heat and surface treatments

- Precision grinding

- Lapping

- Gear cutting

Reasons to use bar turners BENOIT JOLIVET, your partner in France

All of us at bar turners BENOIT JOLIVET are committed to optimising production processes in order to achieve the best possible technical and economic solutions.

We’re capable of machining parts designed in most materials:

- Aluminium, brass and bronze

- Bar turning steel, XC steel and alloys

- Stainless steel

- Inconel

- 100C6 and CrMo

- With or without lead

Thanks to the experience we’ve acquired over the best part of one hundred years, we’ve built up trust-based relationships with many leading players in the automotive, household appliance, rail and sports industries. Most of our customers are located in France, Germany and Slovenia, and we also export further afield to destinations including Mexico.

Our best-known customers include Bosch, BorgWarner, Hidria, Kendrion and Continental.

Got a question? If you’d like to know more about our manufacturing methods or our rates for international orders, don’t hesitate to send us an email (bjo@benoit-jolivet.com) or call us on +33(0)4 50 98 69 11: we’ll be delighted to answer any questions you may have.